HIGH-EFFICIENCY MIXERS FOR

BATTERY PRODUCTION

At a time when electromobility and sustainable energy concepts are becoming increasingly important, lithium-ion batteries are playing a key role. Originally used primarily in smartphones, laptops and tablets, they are now essential in modern electric vehicles.

LÖDIGE develops advanced solutions for battery production – particularly for the critical cathode and anode masses that determine the quality of the batteries. Our high-performance mixers redefine quality standards in production and help the industry to meet the growing demands for efficiency and increased performance.

CHALLENGES IN THE BATTERY PRODUCTION AND OUR RESPONSE

The production of lithium-ion batteries is a major challenge for the industry, mainly due to the extremely high-quality requirements. The use of high-quality and pure raw materials is essential for the fabrication of high-performance batteries. A critical point in the cathode mass is to avoid any contamination by foreign ions such as non-ferrous metals and iron, even in the smallest quantities.

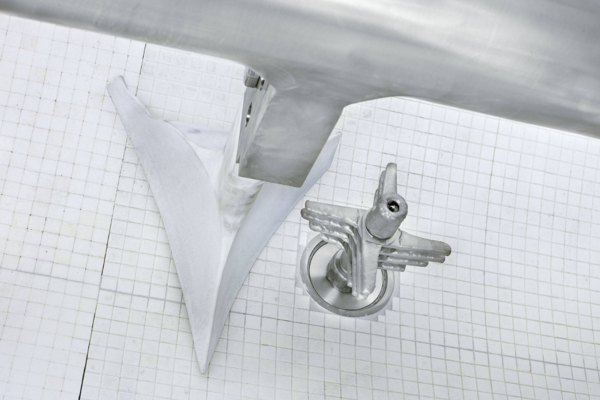

LÖDIGE has more than 10 years of challenging experience in the design and development of special purpose mixers. Our solution to this is the further development of our Ploughshare® Batch Mixer, which operates according to the fluid bed process originally introduced to industrial mixing technology by LÖDIGE. Equipped with mixing shovels specifically adapted to each application, these mixers produce mixes of the highest quality that can be reproduced at any time.

RANGE OF APPLICATIONS

IN THE PRODUCTION CYCLE OF BATTERY

LÖDIGE machines are indispensable both at the beginning and at the end of the production cycle. Ploughshare® Mixers of type FKM are used in the first phase of raw material preparation.

The drum of the Ploughshare® Mixer has a ceramic lining made of special tiles on the inside to ensure high mechanical strength and abrasion resistance. However, due to their complex geometry, the mixing elements cannot be fitted with a lining but are covered with a thin but extremely resistant ceramic coating.

LÖDIGE Vacuum Shovel Dryers also make a valuable contribution to closing the material loop at the end of a battery's life cycle - in the recycling process. After the old batteries have been shredded, the dryers are able to recover liquid components such as electrolytes from the metal-containing "black mass".

LÖDIGE MACHINES FOR THE BATTERY PRODUCTION

Our LÖDIGE machines are of the highest quality and equipped with the latest technology. We also offer customised machine designs for your products and processes.

Ploughshare® Mixer (Laboratory machine)

- Guaranteed LÖDIGE quality

- Attractive value for money

- Functional design

- Ideal for your product and process development

- Extensive range of accessories

Ploughshare® Mixers for batch operation "Universal Design"

- Extremely high mixing quality

- Short mixing times

- Reproducibility of batches

- Gentle product treatment

- High availability

- Low-maintenance mixer concept

- Easy accessibility of all internal mixer components

- Multi-stage processes in one machine

Vacuum shovel dryer DRUVATHERM®

- Intense mixing prevents temperature and moisture gradients within the product

- Maximum heat transfer coefficients ensure excellent dryer performance

- Gentle thermal product treatment in vacuum mode

- Multi-phase process (mixing, granulation, drying, cooling)

- Cost-efficient solvent recovery

Vacuum shovel dryer DRUVATHERM® (Lab machine)

- Reliable scale-up

- Production development under consideration of industrial factors

- “All-in-one process” (mixing, granulation, drying, cooling)

- Intense mixing prevents temperature and moisture gradients within the product

- Short drying times through intense product movement and effective application of thermal energy

- Gentle thermal treatment at low temperatures using a strong vacuum

- Cost-efficient solvent recovery

LÖDIGE SYSTEM SOLUTIONS FOR THE BATTERY INDUSTRY

Benefit from our expertise in customised turnkey solutions. We manage your entire project in an efficient way and with a minimum of interfaces – and take full technical and commercial responsibility for the project. Choose LÖDIGE for your next project and put your trust in our expertise!

YOUR CONTACT PERSONS

In addition to battery production support, we are your partner in the development of integrated system concepts - from consultancy and planning to component manufacture and the realisation of turnkey systems.

We look forward to hearing from you. Together we will find the ideal solution for your needs in battery production.

THE WAY WE WORK:

BEST RESULTS THANKS TO COOPERATION

The outstanding quality of our machines and systems is based on elaborate process design, comprehensive basic engineering and the special construction of our Ploughshare® Mixers and Vacuum Shovel Dryers.

Our belief is that excellence is achieved through cooperation and we therefore work closely with the leading battery manufacturers.

DOWNLOADS

WE ARE CERTIFIED & APPROVED

Our commitment to quality is officially confirmed by recognised testing bodies. Find out more here about our industry-specific approvals and certificates.

LET'S HAVE A CHAT

Do you have any questions, suggestions or feedback? Let us know your request using the contact form and we will get back to you as soon as possible: