PHARMACEUTICAL MACHINERY: STATE-OF-THE ART SOLUTIONS

From precise dosing and the use of the latest analytical and synthesis techniques to genetic laboratories, the production of modern medicines requires state-of-the-art technology and strictest quality standards. At every stage of production - from raw materials to packaging - the safety and efficacy of medicines must be guaranteed to protect patients.

Over the past decades, LÖDIGE has established itself worldwide as a partner for process machines and systems in the pharmaceutical market. High-quality machines, service from experienced staff, our own pharmaceutical Test Centre and a competitive price: this makes LÖDIGE a valuable partner in the pharmaceutical industry. Decades of close cooperation with well-known pharmaceutical manufacturers are proof of our expertise: we have supplied more than 1000 machines and systems for pharmaceuticals.

CHALLENGES IN THE PHARMACEUTICAL INDUSTRY AND OUR RESPONSE

Pharmaceutical production is subject to the world's highest standards of safety, purity and reproducibility. The quality of our services guarantees compliance with these international standards. Within this context, our specific process know-how in mixing, granulation, drying and coating systems forms the basis for innovative system solutions in the pharmaceutical industry.

Customised machine and system design is just as important to us as strict compliance with GMP and FDA regulations.

LÖDIGE GUARANTEES THE SPECIFIED

QUALITY PROPERTIES OF SENSITIVE PRODUCTS

By providing a wide range of different systems and machines, LÖDIGE enables a product-specific process design that guarantees the specified quality characteristics of the most sensitive products. Global market leaders in the pharmaceutical research as well as generic manufacturers, contract manufacturers and smaller specialist companies with niche products rely on the LÖDIGE technology:

We have precise solutions for the entire range of pharmaceutical products, from raw materials to finished dosage forms. Our expertise includes:

- Basic pharmaceutical products

- Excipients / Active ingredients

- Tablets

- Pellets

- Granules

- Particles / Crystals

LÖDIGE-MACHINES FOR THE PHARMACEUTICAL INDUSTRY

LÖDIGE is specialized in machinery for the pharmaceutical industry - with a comprehensive range of mixing, granulation and drying systems, tablet coaters and much more. We manufacture machines and systems on both a production and laboratory scale. An overview of each machine can be found below:

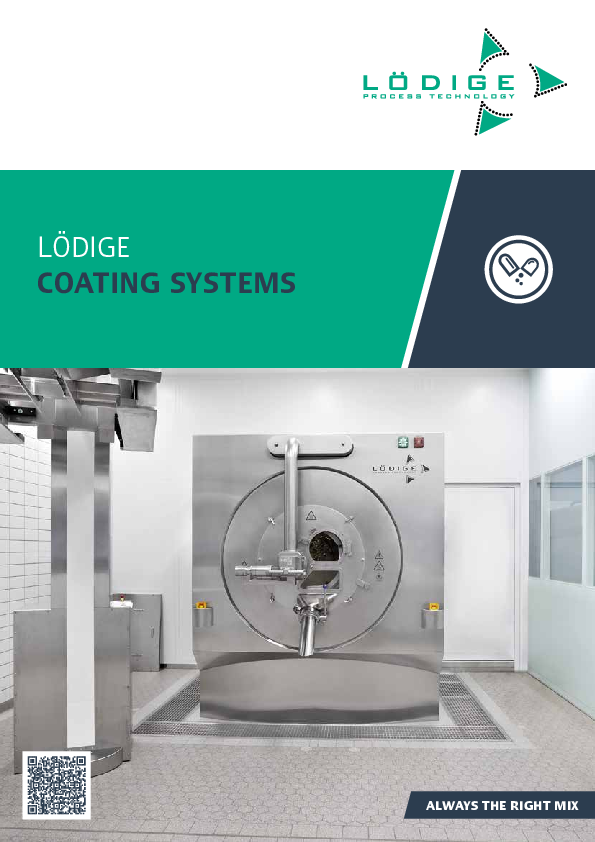

LÖDIGE Coater LC

- Filling level variability without drum replacement

- The extremely low height of the mixing elements permits a high degree of filling level variability.

- Even application and short process times

- The high number of mixing elements and nozzles ensures ideal distribution and leads to low variance in the evenness of application.

- High-speed = Time is money

- The even air distribution throughout the entire drum length ensures that the drying effectiveness is high and permits high spray rates.

- Optimised air routing: A quality improvement

- This air routing prevents spray drying, increases service life for campaign production and reduces the cleaning workload.

- Simple cleaning

- A sophisticated cleaning system and its great mechanical effect make cleaning quick and efficient. This saves time, cleaning agents and energy.

LÖDIGE Coater LC LAB (Laboratory machine)

- Innovative design, great functionality

- Variable filling level between 0.6 and 6.0 l

- High process speed due to high spray rates and high drying capacity

- Even distribution of the suspension

- Process conditions comparable to Lödige production coaters

- User-friendly: Easy handling, intuitive operation

Ploughshare® Mixers for batch operation "Hygienic Design"

- Extremely high mixing quality

- Short mixing times

- Reproducibility of batches

- Gentle product treatment

- High availability

- Low-maintenance mixer concept

- Easy accessibility of all internal mixer components

- Multi-stage processes in one machine

Ploughshare® Mixer (Laboratory machine)

- Guaranteed LÖDIGE quality

- Attractive value for money

- Functional design

- Ideal for your product and process development

- Extensive range of accessories

THE LÖDIGE MIXING GRANULATOR

- Mixing granulator for pharmaceutical products, cosmetics and food

- GMP-compliant design

- Modular WIP system for the machine and all additional components

- Automatic liquid addition in different versions

- New pharmaceutical controls

- Temperature control jacket for heating/cooling

- Integrated sieve on machine outlet

- Vacuum feeder

- Customised ATEX concepts

Mixing granulator (Laboratory machine)

- Laboratory mixing granulator with exchangeable vessel

- Mixing, granulation and temperature control in one machine

- Exchangeable vessels with a volume of 1, 5, 10 or 15 l

- GMP-compliant design

- User-friendly, integrated control system

- Operation-ready system

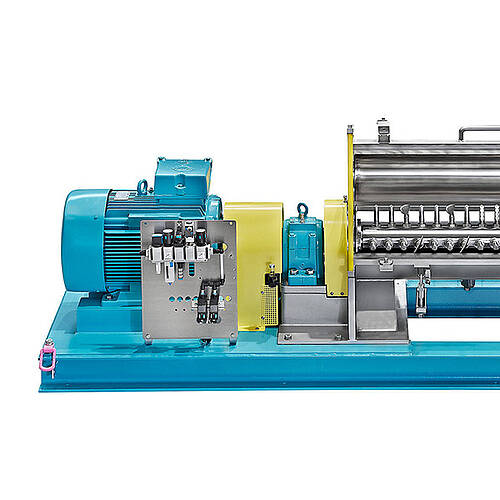

Ringlayer mixer CoriMix® for continuous operation

- Compact machine unit with high throughput

- Extremely high mixing homogeneity

- Versatile application options

- Easy operation and cleaning

- High operating reliability and service life

The Lödige high-speed granulator

- Versatile application options for the pharmaceutical and food industry

- GMP-compliant design

- Usable as a single unit or combined with a cooling mixer

- User-friendly control system with pre-defined process steps

- Many additional options available (CIP system, qualification, etc.)

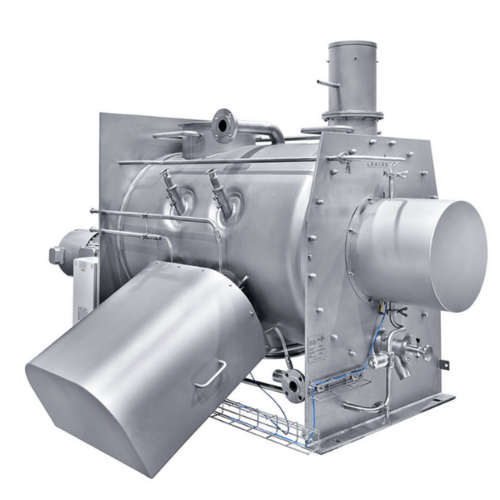

Vacuum shovel dryer DRUVATHERM®

- Intense mixing prevents temperature and moisture gradients within the product

- Maximum heat transfer coefficients ensure excellent dryer performance

- Gentle thermal product treatment in vacuum mode

- Multi-phase process (mixing, granulation, drying, cooling)

- Cost-efficient solvent recovery

Vacuum shovel dryer DRUVATHERM® (Lab machine)

- Reliable scale-up

- Production development under consideration of industrial factors

- “All-in-one process” (mixing, granulation, drying, cooling)

- Intense mixing prevents temperature and moisture gradients within the product

- Short drying times through intense product movement and effective application of thermal energy

- Gentle thermal treatment at low temperatures using a strong vacuum

- Cost-efficient solvent recovery

MIXING, GRANULATION, DRYING AND COATING IN THE PHARMACEUTICAL INDUSTRY

LÖDIGE Mixing Granulators are an important part of the granulation lines of well-known German and international pharmaceutical manufacturers.

As one of the few suppliers to the pharmaceutical industry, we have a large number of feferences for continuous systems for the production of mixes and granules for solid dosage forms. We use continuous systems for direct compression and wet granulation for example.

Our LÖDIGE Coater sets new standards in terms of coating speed, efficiency and fill level variability. All our pharmaceutical machines can be equipped optionally with WIP/CIP systems.

GRANUCON® LINE FOR THE PHARMACEUTICAL INDUSTRY

The GRANUCON® is a complete, continuous production line - from the powder to the finished granules.

RESEARCH AND DEVELOPMENT FOR THE

TECHNOLOGIES OF THE FUTURE AT THE LÖDIGE TEST CENTRE

For process development and scale-up to production scale, we have a pharmaceutical Test Centre at our site in Paderborn/Germany that meets the requirements for GMP compliant test series and small-scale production. The pharmaceutical Test Centre is equipped for mixing, wet granulation, vacuum drying and coating.

YOUR CONTACT PERSON

At LÖDIGE, we believe that our technology and expertise can help you meet the challenges of the pharmaceutical industry. Contact us to find out how we can optimise your production process with our machines and systems.

Our experts are at your disposal to develop solutions tailored to your exact needs.

THE WAY WE WORK:

INNOVATION THROUGH COOPERATION

We are convinced that true innovation and excellent results come from a close and productive partnership with producers. Working directly with pharmaceutical professionals enable us to develop and validate solutions and equipment that are tailored to the specific needs and challenges of the industry.

This approach enables us to adapt to the dynamic demands of the market and to supply solutions that are synonym for efficiency, quality and safety.

DOWNLOADS

WHITE PAPER: ADVANTAGES OF SINGLE POT SOLUTIONS FOR THE PRODUCTION OF PHARMACEUTICAL GRANULES

WE ARE CERTIFIED & APPROVED

Our commitment to quality is officially confirmed by recognised testing bodies. Find out more here about our industry-specific approvals and certificates.

LET'S HAVE A CHAT

Do you have any questions, suggestions or feedback? Let us know your request using the contact form and we will get back to you as soon as possible: