Innovative mixing technology for battery masses and battery recycling

Innovative mixing technology for battery masses and battery recycling

In this article you will discover:

- The challenges of battery raw material preparation

- How specially designed Ploughshare® Mixers ensure optimum homogenisation

- The benefits of ceramic linings and tungsten carbide alloys

- Why high-speed choppers are essential to produce battery masses

- How modern sealing systems increase operational safety

Challenging down to the last detail

The processing of the raw materials required to produce lithium batteries is subject to stringent quality requirements - right up to the limits of technical feasibility. For example, contamination of the cathode mass by foreign ions, especially iron, must be prevented at all costs. LÖDIGE has solved this challenging process engineering task with a special version of the proven Ploughshare® Mixer, of which more than 200 machines have been sold worldwide in recent years.

Electromobility on the rise

Electromobility continues to be a big issue and electric vehicles have become an integral part of our everyday lives. In China, the share of electric cars in new car registrations was already 46% in February 2025. The growing number of electric cars worldwide will require huge quantities of lithium batteries which can only be produced by a massive expansion of existing production capacity. In Europe, too, many new battery production facilities are being built in response to increasing demand.

Processing of raw materials in battery production

In the long production chain for lithium batteries, the processing of raw materials is a first, but decisive step for ensuring the quality of the final product. Today’s lithium battery cathodes consist of a mix of lithium carbonate and mixed nickel-cobalt-manganese oxide to which additives have been introduced. Iron, however, is an undesirable substance. LÖDIGE has now developed a special machine type for homogenizing the cathode mass.

Find out more about the Ploughshare® Batch Mixer FKM

Specially designed batch mixers

This application-specific model is a further development of the Ploughshare® Mixer (batch mixer). It operates according to the mechanically generated fluid bed principle introduced by LÖDIGE in industrial mixing technology. Initially, mixers with a volume of 3000 litres were often used. In the meantime, there is an increasing demand for larger machines.

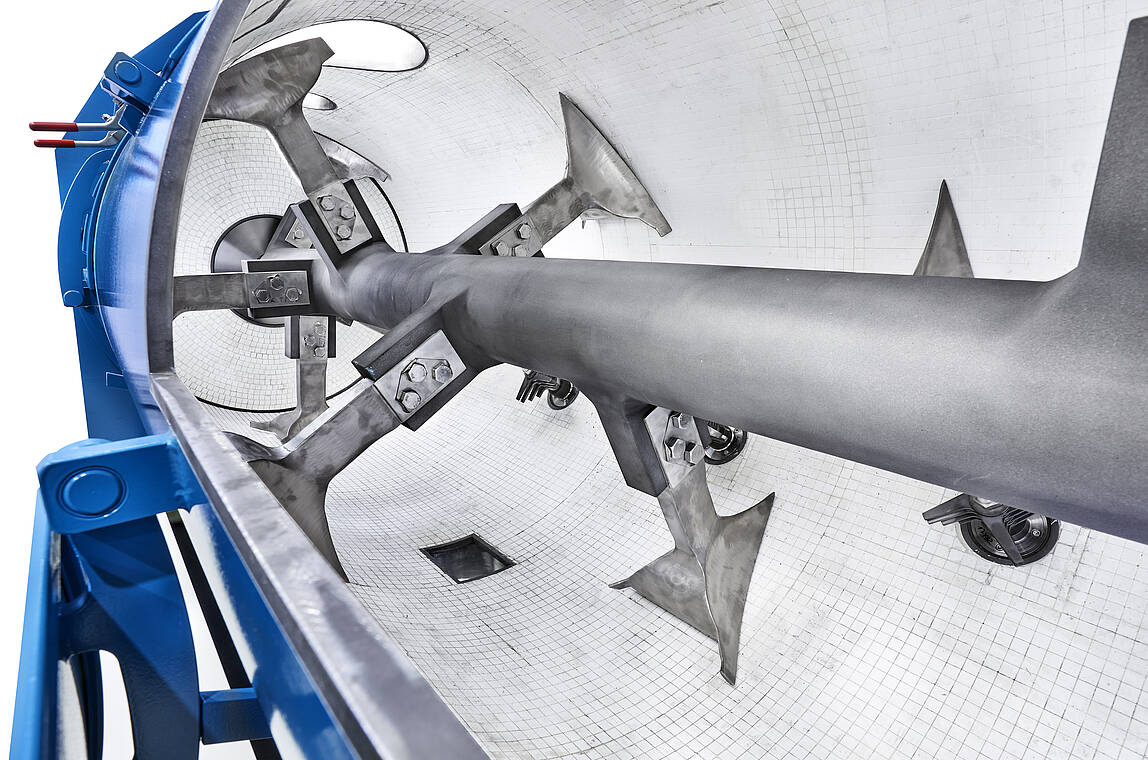

Special tile lining

The drum of the Ploughshare® Mixer has a ceramic lining on the inside. As an alternative to oxide ceramics, coatings made of hard metal alloys are also used as they are particularly robust and wear-resistant. These solutions are specially developed for battery production to achieve optimum results when drying battery masses in our mixers.

High-speed choppers

The high-speed choppers running at up to 3000 rpm and fitted with tungsten carbide welding are of particular importance. Furthermore, to ensure safe operation, modern sealing systems are used to prevent toxic substances from escaping.

Conclusion: Ploughshare® Mixer as a key technology for battery masses and battery recycling

LÖDIGE meets the challenging process of manufacturing lithium batteries with a special version of the proven Ploughshare® Mixer. This machine achieves homogeneous mixing of the cathode masses in the shortest possible time.

All the facts briefly:

- Mixing volumes from 1200 to 13500 litres.

- Use of modern sealing systems.

- Wear-resistant linings with ceramic or tungsten carbide alloys.

- Special choppers for optimum homogenisation.

Would you like to know more? Get in touch with one of our experts to discuss the best way to mix!

Request personalised advice now

![[Translate to English:] Darstellung einer Batterie in einer Hand.](/images/_processed_/8/d/csm_loedige-impulse_recycling-batterie_7cd6b8a7b5.png)