THE LÖDIGE CUSTOMER SERVICE:

YOUR SUCCESS IS OUR GOAL

Welcome to the LÖDIGE Customer Service - your reliable partner for machine maintenance, technical support and much more. With our wide range of services and the commitment of our technicians, we make sure that your production systems always operate smoothly. Benefit from our worldwide support and tailor-made maintenance contracts. You can rely on our expertise to ensure continued productivity and long-term success.

AN OVERVIEW OF OUR SERVICES

- Responsive maintenance and repair service: Ensuring the high availability of your equipment.

- Wear and spare parts: High-quality components for your machines, spare parts, etc.

- Remote maintenance/service level agreements: Efficient maintenance with state-of-the-art solutions.

- Service/maintenance agreements: For new machines and existing machines.

- Process conversion and optimisation: Technical modifications for maximum efficiency.

- Advice on safety standards: According to European directives 2006/42/EC and 2014/34/EU (ATEX).

- DQ/IQ/OQ/PQ: Comprehensive qualification process.

- Calibration service: Precision for your system.

- Training course: Developing competence for your team.

- Process technology support: Expert advice for your process.

- Rental and second-hand machine service: Flexibility and benefits.

GLOBAL PRESENCE

The LÖDIGE Customer Service has no limits. We deliver machines and spare parts on time - worldwide. Our Customer Service Team provides support in many languages - including English, German, Spanish, Chinese, Arabic and Russian.

Wherever your LÖDIGE machine is located, our experts will ensure fast and efficient installation and integration into your production environment. It doesn't matter if your machine is in Germany, Spain, China, India or the USA. The customer satisfaction is our goal, and we will not rest until everything works perfectly.

EFFICIENT SUPPORT: AFTER INSTALLATION TOO

Our maintenance agreements guarantee you continuous support. Our Service Technicians are specialists in carrying out all the necessary work efficiently - whether remotely for PLC-controlled machines or on-site for system conversions, upgrades, or software updates.

They can be seamlessly integrated into your production processes to minimise downtime and maximise the performance of your systems.

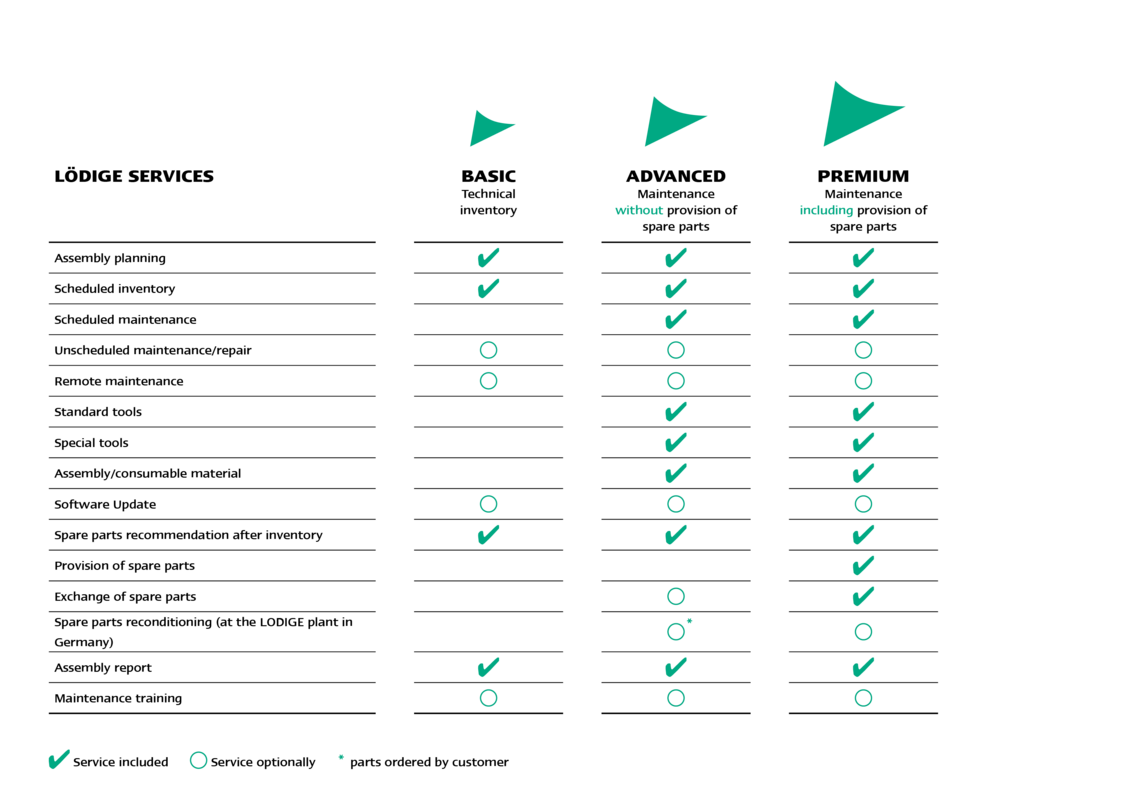

LÖDIGE maintenance agreements

Increased availability and minimisation of unplanned downtimes

A technical inspection carried out by us is a systematic process aimed at checking the condition of your machines and systems to ensure their safety, functionality and efficiency. We ensure your satisfaction with our services.

We optimise the availability and service life of your machines with the following service packages:

BASIC

Technical inventory:

In addition to scheduling, installation planning includes checking the technical documentation, such as operating instructions, maintenance logs and previous inspection reports.

A visual inspection of the machine surface for cracks, corrosion, wear or other visible damage is carried out during the inventory. All components such as moving parts, seals, bearings and other critical components are checked for wear or damage.

All findings are documented, including defects found, tests performed and values measured.

Based on the inspection results, recommendations for maintenance or repair measures and the stocking of spare parts are recorded in the assembly report.

ADVANCED

Maintenance without provision of spare parts

In addition to the scope of the technical inventory, we also carry out maintenance on your machine. The necessary standard and special tools are provided by our service personnel. This ensures fast and high-quality processing.

PREMIUM

Maintenance incl. provision of spare parts

This package also includes the provision of standard spare parts, which are only charged according to consumption. Note: Machine-specific spare parts must be provided by the customer. We provide a corresponding recommendation with the offer of the maintenance contract.

QUALIFICATION

You are in good hands with us for the qualification of your pharmaceutical and food processing equipment. We can support you from Design Qualification (DQ), Installation Qualification (IQ) and Operational Qualification (OQ) through to Performance Qualification (PQ) and periodic recalibration. Our expertise ensures the compliance and performance of your systems.

IT HELPS TO HAVE KNOWLEDGE

Use our training programmes to optimise the operation of your LÖDIGE machines. Learn how to maintain your equipment for greater efficiency and cost savings.

WE ARE CERTIFIED & APPROVED

Our commitment to quality is officially confirmed by recognised testing bodies. Find out more here about our industry-specific approvals and certificates.