Process engineering requirements and solutions for the production of meat substitutes

There are many good reasons to stop eating meat. Consumers see it this way too and are increasingly turning to vegetarian and vegan alternatives. A current forecast by the German online platform Statista predicts a European market volume for meat substitutes of €5.94 billion in 2028. This would correspond to annual sales growth of just under 10 percent [source 1]. This sales growth needs to be served – with efficiency and homogeneity.

Production process

Meat substitutes are mainly based on cereals such as wheat and pulses such as soya, peas or lupins [sources 2 – 3]. The industrial production process for such meat substitutes takes place in several stages: Firstly, the protein sources are ground and mixed with a solvent to separate the protein from the other components. This results in a protein concentrate (with 70 – 80 percent protein density) or isolate (with an even higher protein content). After the largely tasteless protein mass has been dried, powdered additives such as spices or colouring agents are added, depending on the recipe. An extruder then processes the mix into texturised vegetable protein (or for short: TVP) into a granulated, fibrous or chunky shape. This lays the foundations for the perfect meat equivalent.

In an additional step, water, oils or other liquids are added to the TVP to produce meat-like substitutes, e.g. to condition it for the next production steps or to add flavouring. Mixing is carried out by means of the coating process. The individual extrudates are coated by spraying them with the added liquids. Mixing dry additives before extrusion as well as liquids into the extruded TVP therefore play a key role in the quality of the end product.

The production process can generally be carried out continuously or in batch operation. It is also possible to use a combination of both processes in a quasi-continuous operation. The ideal operating mode depends on the respective application and the customer's individual situation. This means that a batch solution is generally easier to implement and offers greater flexibility, e.g. when integrating into existing environmental conditions. Continuous systems, on the other hand, enable higher throughputs with comparatively smaller machines. The larger the production volumes, the more important these advantages become.

Proven batch and continuous mixers

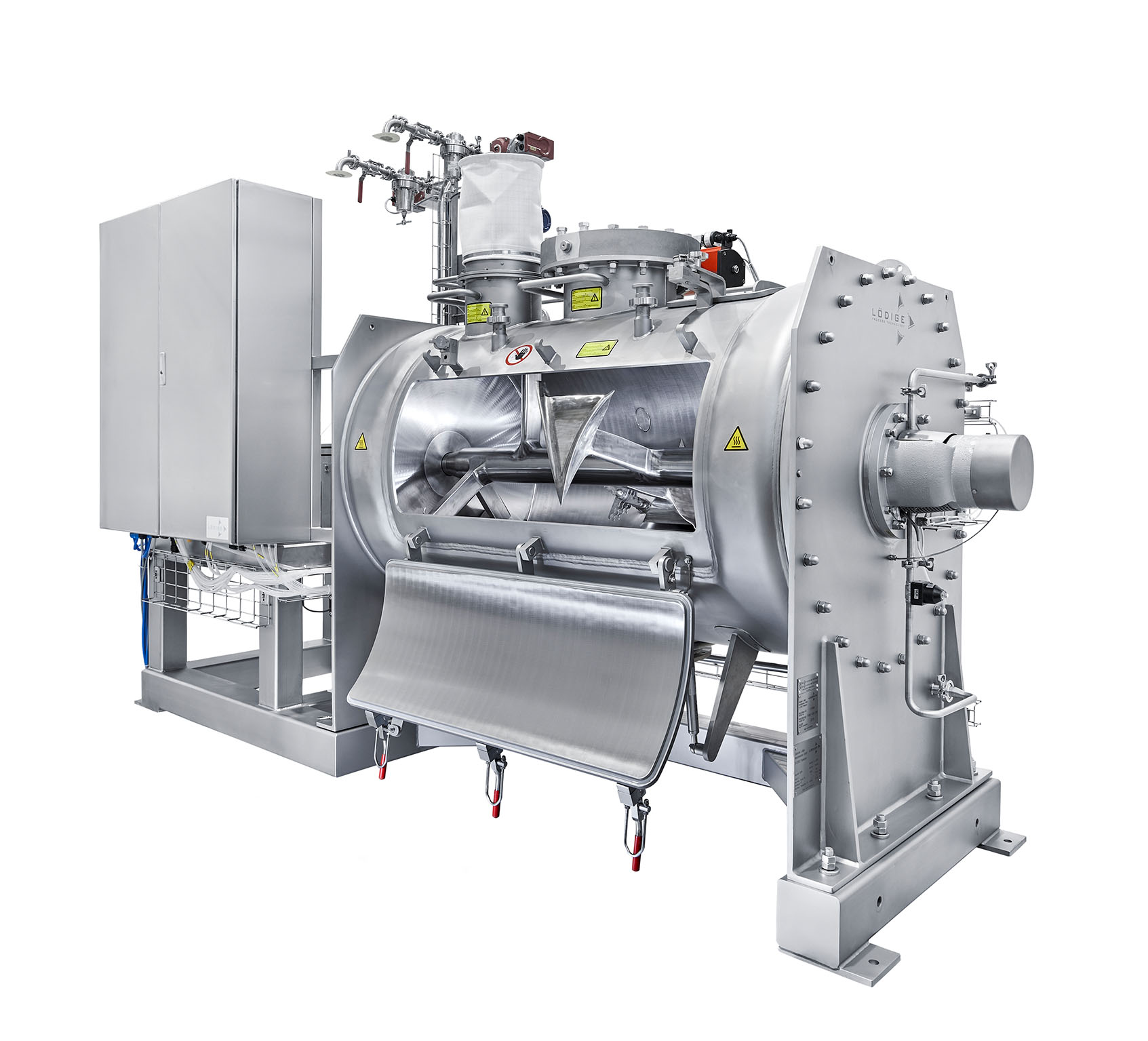

Two model series from Gebrüder Lödige Maschinenbau GmbH are perfect for the production of meat substitutes – from laboratory scale to large-scale industrial realisation. The horizontal LÖDIGE Ploughshare® Mixer offers an optimum solution for batch operation, while the LÖDIGE CoriMix® Mixer skilfully demonstrates its strengths in the continuous process. Their specially developed shovels rotate close to the wall inside a horizontal drum, creating a fluid bed. This process, introduced to industrial mixing technology by LÖDIGE, enables high homogeneity with constant reproducibility and optimum liquid distribution.

Treatment inside the LÖDIGE Mixers therefore offers multiple advantages compared to other mixing methods: Intensive mixing combined with short process times ensures the highest mixing qualities and particularly efficient operation. Residence times, duration of treatment and other process variables can be modified depending on the characteristics being sought.

Batch mixers with a nominal volume of 130 to 3000 litres have already proven their worth many times over. In addition to the general strengths of the fluid bed process, the FKM enables precise temperature control of the raw materials by means of an insulated temperature control jacket on the drum. In addition, the FKM allows liquid components to be added via liquid addition injectors in the effective range of special choppers, which rotate at up to 3000 rpm and ensure ideal distribution of even higher-viscous liquids such as flavourings or liquid greases in the mix. The sturdy design of the mixer ensures long service lives of 25 years and more and minimises maintenance.

The LÖDIGE continuously operated Ringlayer Mixer CoriMix® has also been used successfully in food technology for many years: Low space requirements, high throughputs, automatable process control, easy handling and maintenance, great cleaning options and durability were the focus during its development. A temperature-controlled jacket enables fine tuning of the process parameters and ensures constant conditions even at 500 to 1000 rpm and corresponding friction energy.

Unlike other mixer types, the mixing shaft of a CM system rotates at high circumferential speeds. This accelerates the added product components centrifugally. The result is the formation of a ring layer. Within this concentric layer, there are enormous speed differences between the rapidly rotating mixing tools and the stationary drum wall. This means there is particularly high level of friction in the profile of the ring layer. The application-specific shaped tools of the mixing elements move the product through the mixing drum throughout the process, similar to a plug flow. As this process takes place extremely quickly, the residence times are very short.

Last but not least, CoriMix® technology can also be used at the start of meat substitute production, namely to purify the protein sources. In downstream batch operation, a Druvatherm® Vacuum Shovel Dryer from LÖDIGE can dry the protein concentrates and isolates.

Hygienic design

LÖDIGE Ploughshare® and CoriMix® Mixers are available in different sizes and designs. The customised design of machines and systems is just as much a matter of course as strict compliance with current GMP guidelines and food regulations. Automatic WIP systems for reliable and reproducible cleaning of the mixer are available as an additional option. The cleaning process itself comprises the residue-free removal of any remaining product and material build-up in the entire mixing drum.

However, LÖDIGE does not only supply the mixer(s). As a solution provider, the company also implements entire systems so that the entire process chain from the protein source to the meat substitute can be covered. LÖDIGE supports the customer in the implementation of the entire system, from planning to commissioning.

Sources:

- https://de.statista.com/outlook/cmo/lebensmittel/fleisch/fleischersatzprodukte/europa

- https://landeszentrum-bw.de/,Lde/Startseite/wissen/pflanzlicher-fleischersatz

Author and contact for reader enquiries:

René Rösemeier-Scheumann

Sales Engineer – Life Science Technology

Gebrüder Lödige Maschinenbau GmbH

Elsener Straße 7-9 – 33102 Paderborn, Germany

Phone: +49-5251-309-393

Fax: +49-5251-309-129

E-mail: roesemeier(at)loedige.de

www.loedige.de