Temperature changes during drying and re-humidification Using two machines to achieve energy efficiency

Using two machines instead of one to save energy in chemical production processes may sound paradoxal, but LÖDIGE has now implemented this approach at a German chemical company.

In a multi-stage process chain, performing two or more steps successively in the same machine can be advantageous. In many applications, carrying out synthesis and upstream or downstream processing stages in a single machine and batch can save production time and space. LÖDIGE has already successfully implemented such systems on many occasions.

However, the “single pot process” approach has a disadvantage in one particular application: when there are significant temperature changes. This is because heating and cooling the reactor for each process is very intensive in terms of energy. For example, heating 10 tons of steel by 50°C requires around 70 kWh of energy. Secondly, frequent temperature changes also put considerable strain on the machine.

Solvent-free process at a chemical company

One of our customers was faced with this challenge. This German chemical company needed to process a residual product containing an organic solvent to ensure safe further processing or disposal. To achieve this, the product is heated to over 100 °C under vacuum to ensure that the solvent, having a high boiling point, evaporates completely. To prevent dust explosions, the dried product is cooled below 100 °C and moistened again with water. At higher temperatures, the water would naturally evaporate immediately.

In this case, both steps used to be carried out in a single machine, a Vacuum Shovel Dryer of make LÖDIGE with a capacity of 10 tons. However, the entire process needed to be optimised in terms of energy efficiency for a new production site, meaning that an update of technology was required.

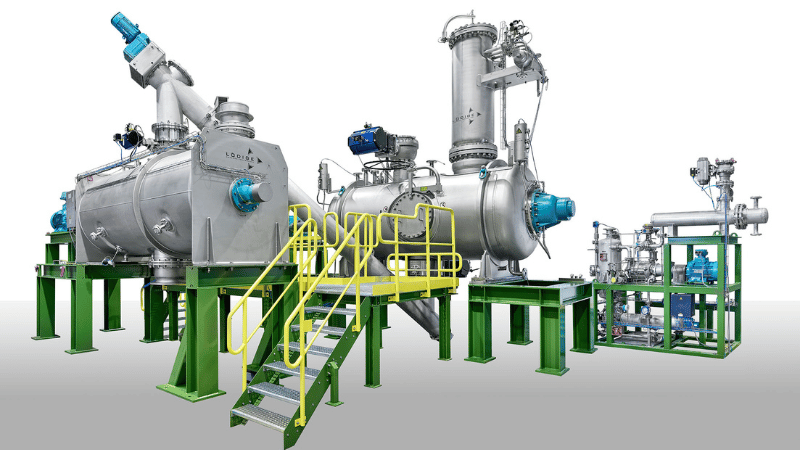

LÖDIGE solved this problem by combining two machines, each operating at a constant temperature: drying now takes place in a heated Vacuum Shovel Dryer. Re-humidification, on the other hand, takes place at much lower temperatures in a Ploughshare® Mixer installed downstream. This increases significantly the energy efficiency of the process. In addition, the machines are subjected to far less thermal stress.

Vacuum Shovel Dryer and Ploughshare® Mixer

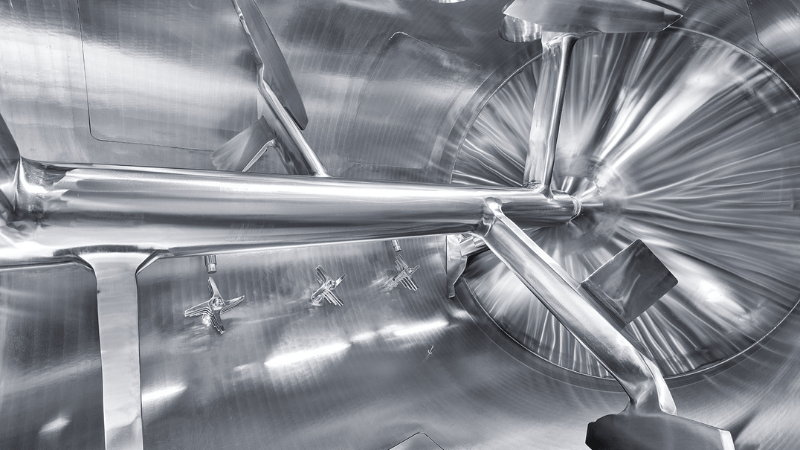

The DRUVATHERM® VT Shovel Dryer is a batch vacuum dryer used for this process. The frequency-controlled mixing shaft optimises the process. Special rotating mixing shovels installed in a cylindrical drum with a heating jacket generate three-dimensional product movement, creating the so-called mechanically generated fluid bed. This results in a high frequency of contact between the product particles and the heat exchange surface, leading to extremely short drying times.

Learn more about our complete solutions

Intelligent product movement ensures intensive contact between individual particles and the heated machine drum while treating the product as gently as possible. Optional rotating choppers are installed on the side of the drum. They break up lumps of product in the event of a phase transition. During the cleaning process, the finest particles entrapped in the solvent vapours are separated by an attached, pneumatically cleanable filter and returned to the product bed for drying. Subsequent humidification takes place in a Ploughshare® Batch Mixer of type FKM. This model is characterised by a low-maintenance mixing shaft, short mixing times, maximum mixing quality and high batch reproducibility. Depending on the application, different options can be selected for the machine equipment, including moistening or liquid addition devices as in this case.

The batch mixer also operates according to the fluid bed process that LÖDIGE introduced to industrial mixing technology. This process ensures excellent mixing and, in this case, homogeneous moistening. The Ploughshare® Shovels arranged on the main shaft rotate as mixing elements in the horizontal, cylindrical drum of the mixer. This generates a three-dimensional movement of the powders, granules or fibrous bulk products, ensuring a rapid and precise mixing while constantly moving the entire product.

The batch mixer is equipped with different tools depending on the application. For specific requirements, it is possible to additionally support the mixing effect of the centrifugal main shaft. For this purpose, separately driven, high-speed rotating choppers are used. These reinforce the breaking up of agglomerates and specific granulation during the process.

Complete system from a single source

LÖDIGE is a solution provider that supplies mixers and implements complete plant systems. The company supports its customers throughout the entire process, from planning to commissioning, helping to achieve the corporate goals in terms of energy efficiency and sustainability by providing optimally sized technology.

In this project, the German manufacturer designed and implemented the entire energy-efficient, solvent-free processing plant. This includes not only the Vacuum Shovel Dryer and the Ploughshare® Mixer for re-humidification but also further equipment like a rotary chute for filling containers, a screw conveyor for feeding the products into the machines, a vacuum pump and a condenser for recovering the organic solvent as well as a PLC system control with corresponding visualisation.

Conclusion

Vacuum Shovel Dryers perform well as “single pot process” reactors in many applications. However, if the task involves significant temperature changes, it is advisable to transfer one process step to a second machine. A German chemical company achieved significant energy savings by converting its plant technology for processing a residual material containing solvents using a DRUVATHERM® Shovel Dryer VT and a Ploughshare® Batch Mixer FKM from LÖDIGE.

Contact us for personal consultation now