Mixing technology for the food industry: solutions for complex recipes

Demand for mixing technology in the food industry is constantly growing. Complex recipes, high hygiene standards and a growing range of ingredients require sophisticated solutions. The LÖDIGE Ploughshare® Mixer of type FKM is a reliable and high-performance solution that sets new standards in terms of efficiency and hygiene.

Mixing bouillon cube ingredients: when versality is required

Instant soups and granulated stock or broth are among the classics of fast food. However, this simple product has a highly complex manufacturing process: stock, broth and bouillon mixes contain many different ingredients that vary greatly in consistency and composition. Production requires high-performance and flexible mixing technology, ranging from dry powders and melted fats to aromatic oils and liquids.

The key here is homogeneity. To achieve the perfect product, it is essential that all ingredients are evenly distributed, regardless of their individual properties.

Ingredients typically used in the production of bouillon mixes:

- Powder with high salt and sugar content

- Spices and colouring substances

- Flavouring oils and lecithins

- Melted fats such as palm or chicken fat

- Starch components that need to swell in a specific way.

This variety necessitates precise interaction between the machine, process and recipe.

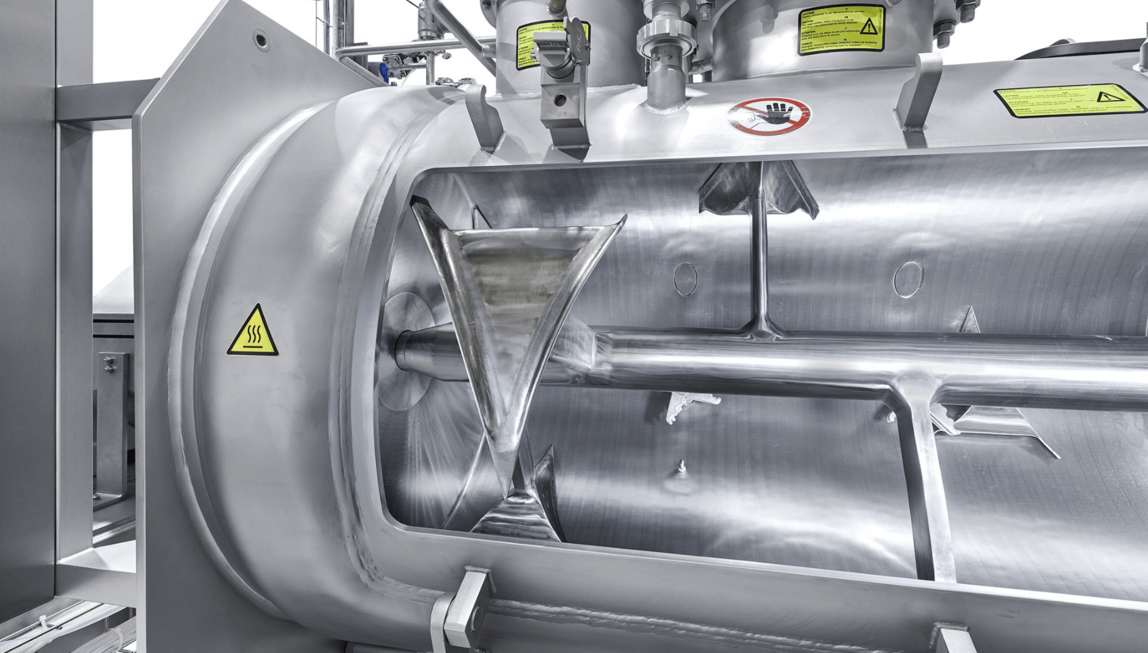

LÖDIGE Ploughshare® Mixer: efficiency at its best

The Ploughshare® Mixer type FKM operates according to the principle of a mechanically generated fluid bed, a concept introduced by LÖDIGE to the field of mixing technology. Thanks to the special arrangement of the mixing elements on the mixer shaft, this mixing principle ensures an intensive but gentle mixing of the individual product components. This means that even sensitive ingredients can be incorporated without any problems – an important advantage in the production of food supplements.

Find out more about the Ploughshare® Mixer type FKM

Hygienic Design as a standard

In addition to pure mixing performance, hygienic processing is a decisive factor, particularly in the food industry. The FKM mixer meets all the requirements of hygienic design as defined by the EHEDG. This applies not only to cleaning, but to the entire system design.

Characteristics for hygienic production:

- Completely stainless steel design

- Product-contact surfaces with roughness < 0.8 µm

- Air-flushed, low-maintenance shaft seals

- Large inspection and cleaning doors

- WIP/CIP-compatible cleaning (automated cleaning possible)

Success story: a major project in West Africa

A food manufacturer in West Africa invested in 18 LÖDIGE FKM mixers, demonstrating the impressive performance of our mixing technology. The challenge was to produce a wide variety of mixes in large volumes, ranging from instant soups to bouillon.

In short: high quality for challenging recipes

Mixing bouillon ingredients, spice mixes and functional ingredients is one of the most complex tasks in food production. The LÖDIGE Ploughshare® Mixer combines technological precision with hygienic safety, making it suitable for a wide range of applications. Whether powder mixers for foodstuffs, mixers for dry soups or systems for producing food supplements: LÖDIGE supplies the food industry with reliable, high-performance mixing technology.