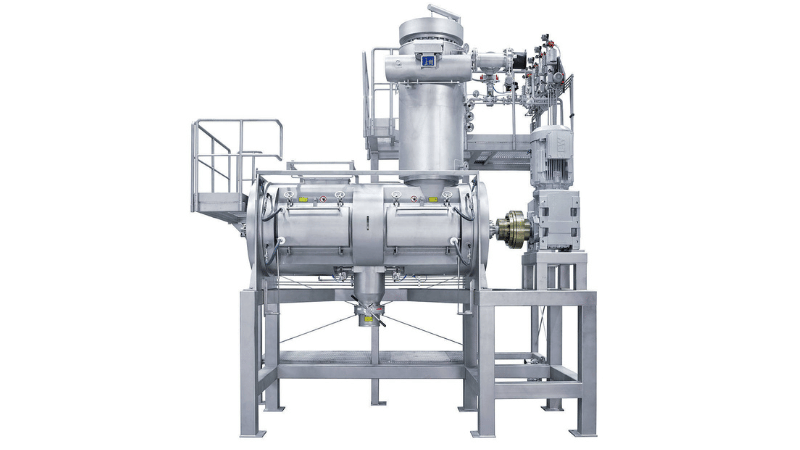

LÖDIGE Vacuum Shovel Dryer VT Advantages of processes in chemical and pharmaceutical applications

As requirements in the chemical and pharmaceutical industries are increasing, the Vacuum Shovel Dryers of type VT made by LÖDIGE are coming into focus. Compared to conventional drying processes, vacuum drying offers a wide range of advantages in terms of process. These include low drying temperatures that are gentle on the product, high evaporation rates and shorter process times in the end.

The advantage of performing vacuum drying in a horizontal Shovel Dryer is that it combines the drying process with the benefits of a horizontal Ploughshare® Mixer. The mixing tools allow mixing precision of 1:100,000 or higher, providing crucial support for the drying process by ensuring a constant exchange between the heating surface and the product. This enables highly effective heat transfer into the moist product.

Learn more about the LÖDIGE Vacuum Shovel Dryer VT

Significantly larger heat exchange surface

Compared to a vertically arranged drying system, the horizontal dryer has a larger heat exchange surface which contributes to shorter drying times. It also has various options for liquid addition and distribution, making it ideal for granulation processes.

Thanks to its pressure-resistant design, the machine drum can also be used to carry out chemical reactions that require overpressure operation or generate it during process. The machine concept also includes filling and emptying via an integrated sieve mill for preliminary treatment of the product or size calibration of the granulate.

Many applications and processes in the chemical and pharmaceutical industries can be performed in the Vacuum Shovel Dryer of type VT in an optimal manner. The following examples demonstrate this.

Drying of chemicals and active pharmaceutical ingredients:

Chemicals or active pharmaceutical ingredients (APIs) often have a relatively high moisture content due to previous processing steps. This must be significantly reduced before they can be processed into a final product. The Vacuum Shovel Dryer is ideal for this purpose thanks to its high evaporation rates and drying performance as well as its suitability for low-temperature drying in case of temperature-sensitive products such as hormones, plant extracts and vitamins. The drying process for chemicals and APIs often involves evaporating solvents creating an atmosphere that could lead to explosions in the dryer. However, this can easily be managed due to the vacuum atmosphere inside the machine.

Containment and single pot applications:

When manufacturing toxic chemicals or pharmaceutical dosage forms containing highly potent active ingredients (e.g. oncology drugs), it is crucial to protect the operator and contain the product. The Vacuum Shovel Dryer is ideal for these requirements as it enables multiple process steps to be carried out within a closed system.

Pre-weighed products are filled into the dryer where process steps such as mixing, granulation, reaction, drying and sieving can be carried out continuously, without the need for product transfer or additional machines. Containment flaps or single use equipment ensure operator protection during product feeding and discharging. The effectiveness of the containment design is certified by a SMEPAC testing.

Production of effervescent granules and tablets:

In the production of effervescent products, a chemical reaction is initiated once the premix and the granulation process have been completed. This reaction releases carbon dioxide. After a short time, the reaction is interrupted by the sudden evaporation of the product's moisture. The Vacuum Shovel Dryer is ideal for this application as it can be used for mixing, granulation and rapid evaporation by applying a high vacuum. After being discharged from the machine, the dry granules can be put through a sieve mill for further treatment.

Would you like to find out more? Get in touch with one of our experts to discuss the best way to mix!

Request personalised advice now