Efficient mixing technology for veterinary chewable tablets

You will now find out:

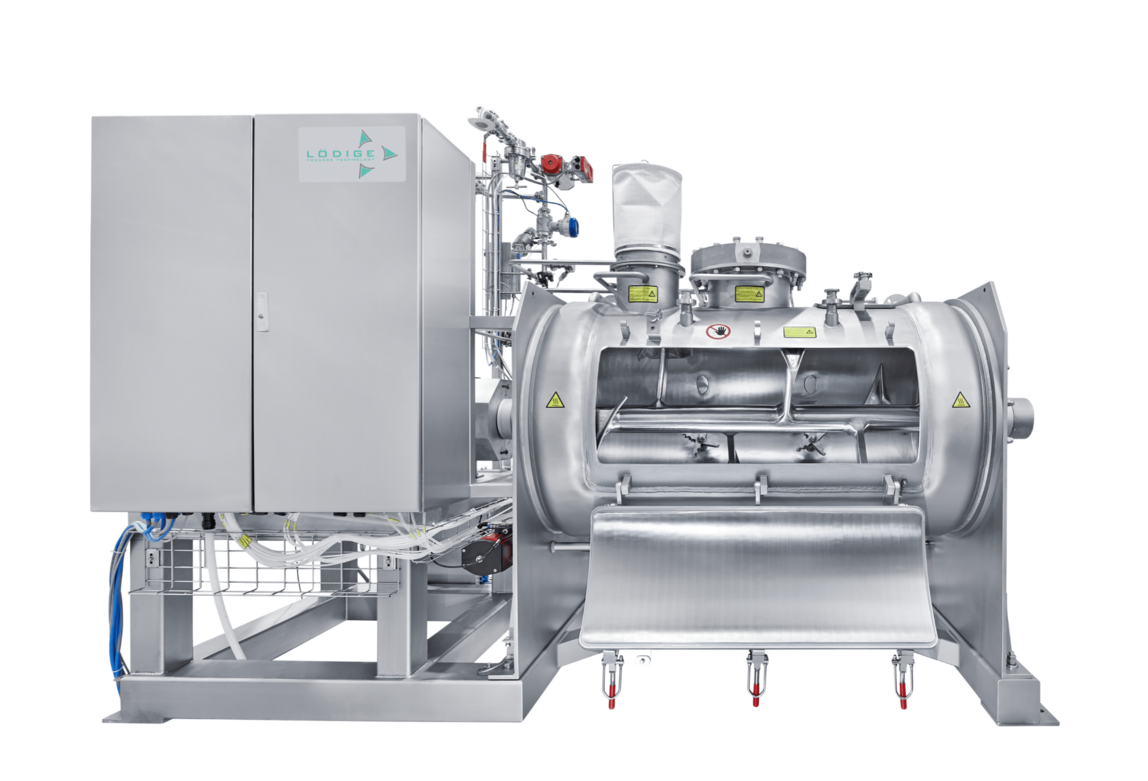

- How the LÖDIGE Ploughshare® Mixer can be used most effectively to produce veterinary chewable tablets.

- What advantages result from this efficient process.

- Why hygienic design is particularly important.

Production of veterinary chewable tablets in a Ploughshare® Mixer

The demand for veterinary products is increasing worldwide, as is the need for efficient and hygienic manufacturing processes. The example of chewable tablets for dogs and cats shows that Ploughshare® Mixers are particularly suitable to meet these specific requirements.

More about the Ploughshare® Mixer of type FKM for batch operation

Market potential for veterinary products

Pet owners worldwide spend over 135 billion euros on their beloved pets. In the USA alone, the figure is almost 60 billion and in Western Europe around 30 billion per year, and this trend is rising. A significant proportion of this expenditure is accounted for by veterinary medicines.

Specialised manufacturers are responding to this growing demand by expanding their production capacities and optimising their processes to make them more efficient. This applies not only to the production of chewable veterinary tablets, but also to the mixing and granulation of human medicinal products which must be produced to the highest hygiene standards.

Raw materials and process

From a process perspective, such tablets consist mainly of dry raw materials and one or more liquid components. In the basic formulation, active pharmaceutical ingredients (APIs) or other additives such as vitamins or flavourings are added to the base product (corn starch or protein powder for example). The first intermediate product is a powdery dry mix.

The Ploughshare® Mixer offers versatile options for adding and distributing liquids into the dry product. In a second step, oils and melted components (PEG for example) are added to the product, creating a dough-like mix. The product is then thermally treated with the aid of the temperature control jacket until the desired consistency is achieved. It is then transferred to a moulding machine for further processing.

Advantages of the Ploughshare® Mixer

- High efficiency due to the mechanically generated fluid bed which ensures the shortest mixing time with maximum homogeneity

- Various possibilities for adding liquids

- Heating or cooling of the product using a temperature control jacket

- GMP compliant machine design

- Easy machine cleaning thanks to CIP (Cleaning in Place) and WIP (Washing in Place) sytems

Would you like to learn more? Contact our experts for individual advice on the optimal mixing strategy! Find out which mixing technologies are suitable for the production of veterinary chewable tablets and why. Read now!