Mixing waste materials: precision for efficient recycling

Precise sewage sludge conditioning: achieving the right balance for optimal results

Where waste used to be simply disposed of, a highly complex recycling process now begins. In Bottrop/Germany, the Emschergenossenschaft, a municipal water board, operates one of the largest sewage treatment plants in Europe – setting standards for sustainability, energy efficiency and innovative mixing technology. Sewage sludge is no longer considered as a waste product, but rather a valuable source of energy. However, it must be optimally conditioned to generate electricity and heat. The LÖDIGE Ploughshare® Mixer is the perfect solution for this: it ensures the exact structure and homogeneity required for efficient thermal recycling.

The Bottrop sewage treatment plant – one of the largest in Europe

Almost 10,000 sewage treatment plants ensure clean water in Germany. Public sewage treatment plants alone treat over 10 billion cubic metres of wastewater per year. One of the largest of these is the Bottrop sewage treatment plant. With a capacity of 1.3 million population equivalents (PEs), it treats an enormous amount of up to 8,500 litres of water per second.

The challenge of sewage sludge: recycling instead of disposal

This process requires a lot of energy and generates large quantities of sludge. 220,000 tons are produced annually at the Bottrop sewage treatment plant and its associated facilities. These quantities must be treated and recycled efficiently on site. Due to the high demand for climate-friendly operations and the increasing number of legal requirements, this municipal water board decided in favour of future-oriented solutions at an early stage.

Setting the course for an energy-self-sufficient sewage treatment plant

Sewage treatment plants are traditionally considered to be energy guzzlers. With an annual electricity requirement of 35 million kilowatt hours, the energy consumption of the Bottrop sewage treatment plant is equivalent to that of a small town of 35,000 inhabitants. To reduce this demand sustainably, this sewage treatment plant is focusing on innovative processes such as producing bio natural gas from sewage gas. The vision is for an energy-self-sufficient sewage treatment plant that intelligently combines solar, wind and sewage gas technologies.

Thermal sewage sludge recycling as a sustainable energy source

Even after the separation of the digester gas, sewage sludge remains a valuable energy source. The sewage treatment plant uses thermal recycling to this end, generating electricity and heat through controlled combustion – an important step towards self-sufficiency and climate protection.

DS content and homogeneity as success factors

Precise conditioning of the sewage sludge is crucial for efficient thermal recycling. The dry substance content (DS content) influences both the combustion rate and the energy content. The higher the DS content, the more solid fuels are contained – which increases efficiency and calorific value. Emission control is also significantly influenced by the DS content. In addition, there are requirements for homogeneity and lumpiness which must be met by targeted mixing technology.

Test series for optimal sewage sludge conditioning

In 2019, the Bottrop sewage treatment plant launched an extensive series of tests. The aim was to develop an optimal process for conditioning sewage sludge that meets all requirements for energy efficiency, sustainability and mixing quality. The result: the LÖDIGE Ploughshare® Mixer of type KM DW for continuous operation impressed in all respects.

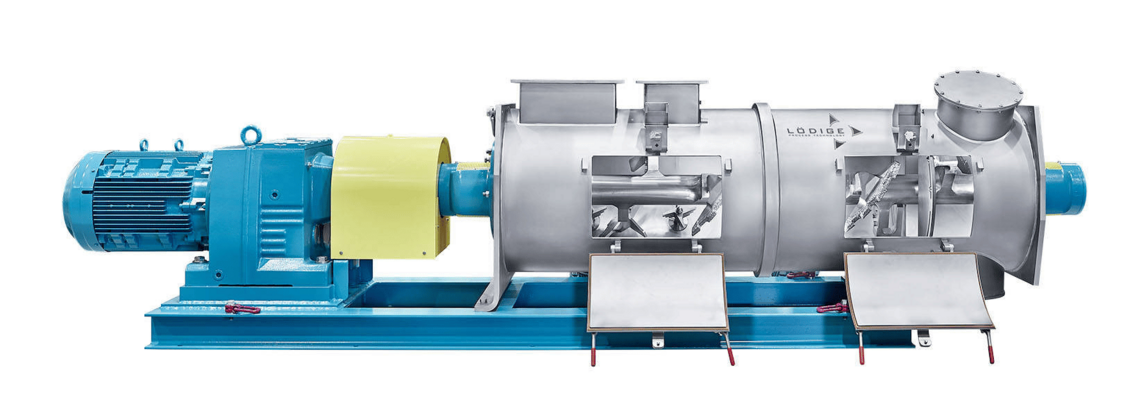

Ploughshare® Mixer: the key to sustainable sewage sludge

LÖDIGE mixers are based on the proven fluid bed process which ensures maximum homogeneity with a short residence time. Specially developed shovels generate an intensive mixing bed in the horizontal drum. Even with a dry substance content of 52 percent i.e. when the sludge becomes viscous and dough-like, the mixer ensures a conveyable consistency and defined particle sizes – without any sticking or clumping.

Continuous process saves energy and ensures quality

Two LÖDIGE KM 600 DW Ploughshare® Mixers are in use in Bottrop. They operate continuously and energy-efficiently. Automated operation and solar thermal pre-drying make the entire process sustainable and economical – a model for modern sewage sludge recycling.

Learn more about Ploughshare®-Mixer type DW for continuous operation

Reliable feed for thermal recycling

After mixing, the sewage sludge is transported via a screw conveyor to a throw feeder and then to the fluid bed furnaces of the adjacent incineration plant. Since commissioning in 2020, the process has been running smoothly and has been continuously optimised in collaboration with LÖDIGE.

Future-proof thanks to efficient mixing technology

In the past, coal had to be added to sewage sludge - today, targeted conditioning is sufficient. With the LÖDIGE Ploughshare® Mixers, operators ensure that the sludge has exactly the properties required for sustainable thermal recycling. A plus for the climate, economic efficiency and future.

Conclusion: Turning waste into the future

Thanks to precise mixing technology and innovative processes, sewage sludge can be transformed into a climate-friendly energy source. The Bottrop sewage treatment plant proves this: Even major challenges can be solved sustainably if you have the foresight and the right technology.