Production of meat substitutes – according to EHEDG guidelines

Meat substitutes are more in demand than ever - but their production is a challenge. Sophisticated production processes and high-precision mixing technologies are required to ensure that vegan alternatives made from raw materials such as wheat, soya or peas have the desired consistency, the right taste and a uniform texture.

But which processes guarantee optimum homogeneity, efficiency and quality?

In this article you will discover:

- Which challenges are faced during production.

- Which steps are necessary in the production of meat substitutes.

- Which LÖDIGE mixer ensures efficient and homogeneous processing.

Whether you work in food production or are interested in the production technology for plant-based alternatives, this article will give you a practical insight into the main mixing processes used in the production of meat substitutes.

Why vegan alternatives to meat are growing

Whether in the form of vegan schnitzel, minced meat alternative or powder, plant-based meat substitutes are booming. More and more people are consciously choosing vegetarian or vegan alternatives to meat. There are many reasons for this. The most important are health aspects, ethical motives or environmental factors.

One thing is certain: the market is growing rapidly. A forecast by the German online platform Statista predicts a European market volume for meat substitutes of €5.94 billion in 2028. This represents annual sales growth of almost 10 percent.

But to convince consumers, plant-based alternatives need to be produced to the highest standards.

The main challenges in the production of meat substitutes

Each step of the production process must be precisely coordinated to imitate the taste, texture and quality of meat. But what are the obstacles in this way?

- Consistency and texture: plant proteins have different structural properties to animal proteins. To achieve a fibrous, meat-like structure, the production process must be optimised.

- Homogeneous mixing: only an even distribution of all the ingredients guarantees that the taste, colour and texture remain constant throughout the batch and that the extrudates are always of the same quality.

- Efficiency: increasing demand requires production at high throughput rates in order to produce large quantities in an economic manner.

- Hygiene standards: the production environment has to meet the highest hygiene requirements to ensure the quality and safety of the final product.

Are you wondering how to successfully meet all these challenges? The key is a well-designed production process - combined with the right mixing technology.

The production process of meat substitutes – step by step

From protein extraction to the finished alternative: the production of meat substitutes takes place in several stages. Each step influences the texture, taste and quality of the final product.

- Protein extraction: cereals (wheat) and pulses (soya, peas, lupins) are ground and mixed with a solvent to obtain protein concentrates (70-80% protein density) or protein isolates.

- Drying and addition of additives, conditioning of the protein: after drying, the protein is mixed with spices, vitamins and minerals or colouring agents to optimise the taste, biological value and texture of the end product. In this step, the protein powder can also be preconditioned with water in the mixing step to significantly simplify and speed-up the subsequent extrusion process.

- Extrusion: the protein mix is further processed in an extruder under pressure and temperature to produce a textured vegetable protein (TVP). Depending on the process parameters, the TVP can have a granulated, fibrous or lumpy structure - a key factor in the meat-like consistency of the final product. A distinction is made between HMMA (high moisture meat analogue) and LMMA (low moisture meat analogue) depending on product requirements.

- Conditioning and coating: In the final step, oils or other liquids such as marinades are added to the TVP to produce meat-like substitutes, for example to condition it for the next production steps or to add flavour.

Crucial in every step: the right mixing technology for optimum product quality.

Contact us for non-binding advice

Which LÖDIGE mixer is suitable to produce meat substitutes?

At LÖDIGE we provide a practice-proven machine ideally suited for the production of meat substitute products and that can be adapted to the production requirements.

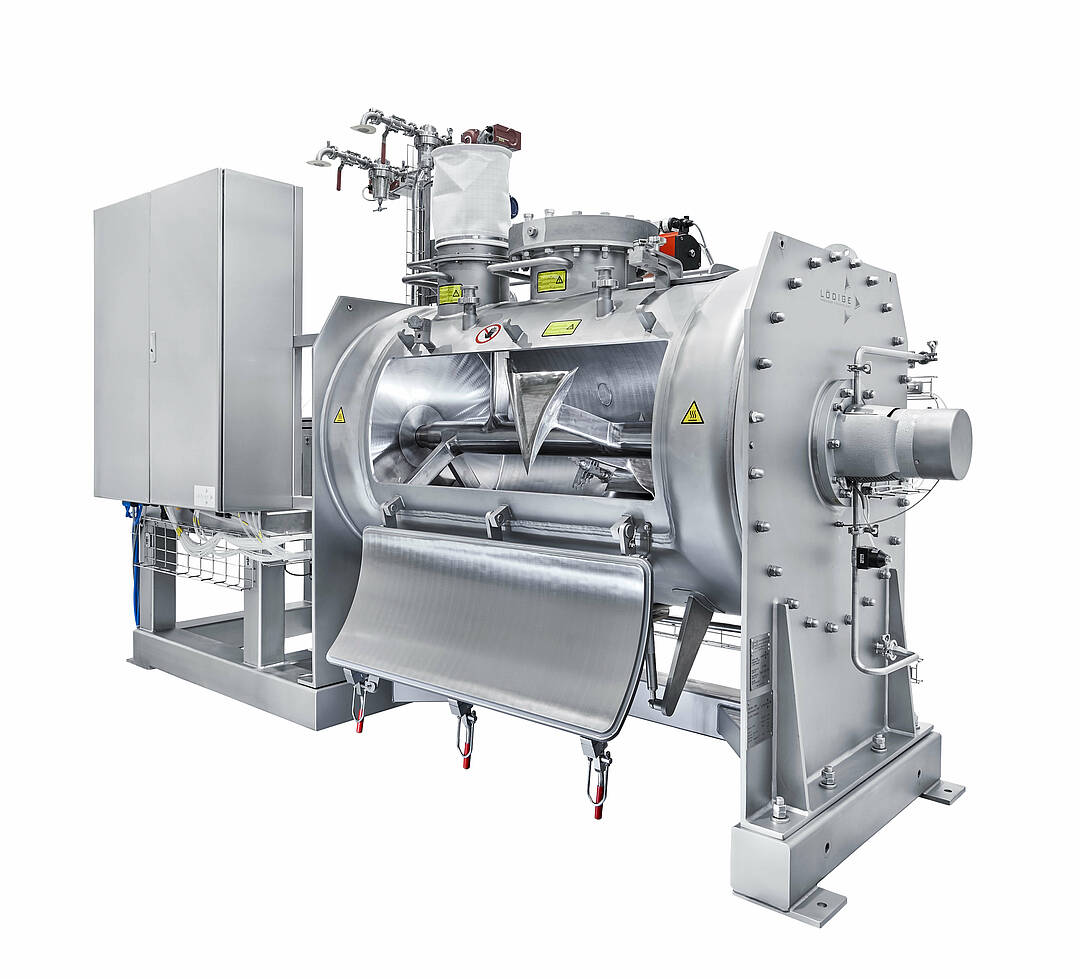

Ploughshare® Batch Mixer type FKM

The Ploughshare® Batch Mixer FKM is the ideal choice for manufacturers who require maximum flexibility and precise process control. This system enables high mixing homogeneity as well as ideal addition and distribution of liquid components into solid mixes.

The most important facts briefly:

- Ideal for batch operation with total volumes from 130 to 3000 l

- Homogeneous mixing achieved by the mechanical fluid bed process

- Precise temperature control thanks to the heating jacket with guideplate system

- Addition of liquid components, e.g. via special liquid addition lances above the choppers which distribute the liquids homogeneously in the powder

- Durable design with a service life of up to 40 years

Find out more about the Ploughshare® Batch Mixer FKM

The LÖDIGE Ploughshare® Mixer is available in various sizes and designs. Customised design of machines and systems is as much a matter of course as strict compliance with current EHEDG guidelines and food regulations.

Hygiene & quality standards in meat substitute production

Hygiene standards and EHEDG guidelines play an important role in food production. LÖDIGE mixers meet the highest quality standards and ensure efficient, safe and legally compliant processing of meat substitute products.

To avoid residues and cross-contamination, the systems are equipped with automated WIP or CIP systems. These provide fast, thorough and reproducible cleaning.

In addition, the durable design of the LÖDIGE mixers ensures maximum operational reliability and low maintenance requirements. Thanks to the robust construction with high-quality materials, the machines are designed for a long life with minimum wear. This reduces downtime and significantly lowers operating costs.

Conclusion: Efficient mixing technology as a success factor in meat substitute production

The production of meat substitute products requires precise coordination of raw materials, mixing technology and process control. The LÖDIGE Ploughshare® Mixers provide the right solution for every production requirement - flexible, efficient and hygienically safe.

Would you like to find out more? Get in touch with one of our experts to discuss the best way to mix!

![[Translate to English:] Verschiedene Fleischersatzprodukte und Gemüsesorten auf einem Tisch.](/images/_processed_/9/e/csm_loedige-impulse_herstellung-fleischersatzprodukte_971d5b4dfa.jpg)