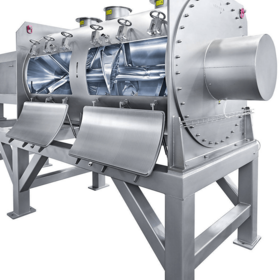

Lödige Ploughshare® Mixers for batch operation"Hygienic Design"

We develop customised solutions, adapted perfectly to your application and product, for any of your tasks.

- Extremely high mixing quality

- Short mixing times

- Reproducibility of batches

- Gentle product treatment

- High availability

- Low-maintenance mixer concept

- Easy accessibility of all internal mixer components

- Multi-stage processes in one machine

Machine type

The Ploughshare® Mixer for batch operation uses the mixing and fluid process introduced to mixing technology by Lödige. High-quality mixes are achieved through equipment with tools which are adapted perfectly to the respective task.

For the sizes, please refer to the machine flyer.

Ploughshare® Shovels arranged on a shaft in a special system rotate as mixing elements in a horizontally fitted, cylindrical drum. The size, number, positioning, geometrical shape and the peripheral speed of the mixing tools are adapted to each other such that they cause a three-dimensional movement of the components. The turbulence generated in the mix through this process results in quick and precise mixing. All material is constantly gripped by the mixing tools to prevent dead zones or zones with poor movement in the mixing chamber.

An application-specific design of the mixing tools and adaptation of the mixing shaft speed permit highly flexible applications of the Lödige Ploughshare® Mixer, be it for treatment of bulk goods (powdered, grainy, fibrous) or for treatment of substances capable of being pumped.

Even components with extremely different bulk densities and structures can be mixed.

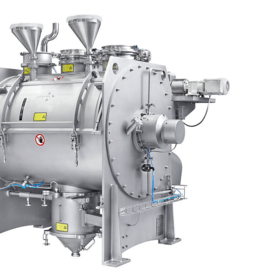

Special tasks may require additional support for the mixing effect of the mixing unit. This support is provided by separately driven, high-speed choppers, which break up agglomerated material and permit systematic granulation during the process in conjunction with the mixing tools.

Liquid components can be added into the product in motion by the means of diverse feeding systems. Pipes for large liquid quantity or nozzles for smaller quantity in general are used. Due to exact positioning, the wetting of the mixer wall and main mixing shaft is avoided as far as possible. Choppers support the distribution effect of the liquids.

A product is automatically granulated when liquids are added to products which turn sticky in contact with a liquid or if they contain binding agents. This granulation effect can be more or less pronounced. Usually the bulk density of the product is increased as soon as it is subsequently dried. The particle size can be adjusted in a wide range depending on the product properties. The particle size can be increased too by addition of liquid or powder in a repeated manner. The use of choppers in such granulation processes can be of advantage. The liquid added is initially distributed in an effective manner, then the particle size is built up more homogeneously and finally the structure of each particle is more compact.

The intensive product movement enables the addition of liquid components to ensure coating of the particles. Molten fat for example can be preferably spread in a liquid form onto the particle surface in order to then recrystallize while cooling down. Cooling is performed in an effective manner by using liquid nitrogen or carbon dioxide snow which is added directly into the product. Further coating processes, like reaction coating, are deemed possible too.

The melting of the coating agent in a powdery product is also feasible in a mixer by heating up the powdery product to the melting point of the coating agent and then cooling down.

- Use of various materials based on their application (from structural steels to stainless steels to special materials)

- Chopper devices

- Jacket for heating and cooling

- Addition of liquids to solids (moistening + granulation)

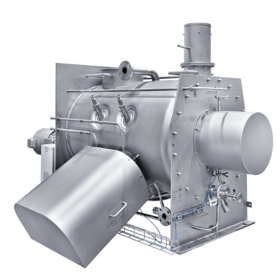

- Batch mixer with large feeding door for manual feeding

- The machines are suitable for nearly all explosion protection zones

- Large inspection door

- Cleaning systems (WIP)

- Partial systems with feeding and/or draining systems

- Modern, user-friendly control system

Features "Hygienic Design"

- High surface quality, Ra < 0.8 µm

- All materials in contact with the product have FDA approval

- Easy to clean (no “dead zones” in the product area)

- Practically complete draining possible

- Electrical control system according to GAMP5 requirements

Areas of application

Lödige Ploughshare® Mixers are used for different mixing tasks in practically all industries. We have delivered over 35,000 machines in 80 years. This is a small excerpt of our applications in the

- oven-ready flours and baking aids

- dry soups and bouillon powders

- flavourings, spices and table salts

- granola and vitamin products

- fruit teas and classic mixes

- cocoa and fruit drinks

- candy, filling and chocolate pastes

- soft cheeses and cheese spread

- decorative sugar and crispy coating

- eye shadow and facial powder

- hair dye and bath essences

- mascara and lipsticks

- tablet compounds

- raw materials for implants

- pre-mixes for tablet compounds and active components with high mixing qualities

- granulation and drying of tablet compounds

- film and sugar coating of tablets, capsules and pellets

- vacuum drying of temperature-sensitive products and active components

- effervescent powders and granulates in a “single-pot process”

Downloads

Ploughshare® Mixers for batch operation

Ploughshare® Food Mixer for batch operation, "Hygienic Design"

Ploughshare® Batch Mixer for pharma applications