Our machine finder

Find easily the machines that are relevant to you – with our machine finder you can quickly reach your destination!

In a few steps!

to your solution!

Our solutions for your project

No suitable machine found for your selection!

Are you interested in a personal consultation?

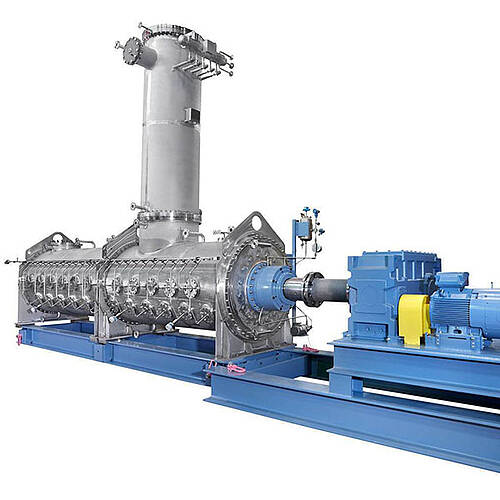

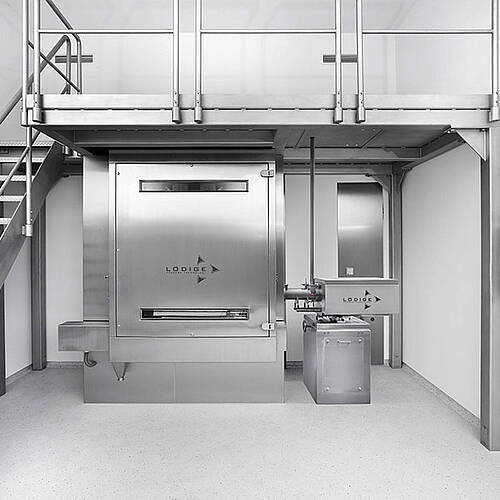

Granulation dryer for continuous operation

Combination of convection and contact drying Process management at low temperatures Gentle product treatment Simultaneous product granulation possible Reliable reproducibility of product quality Suitable for stripping processes High system availability

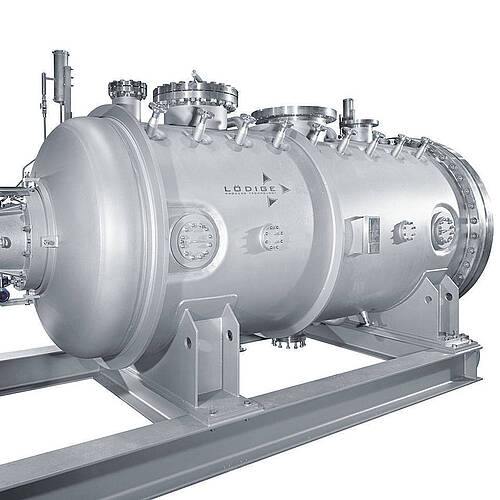

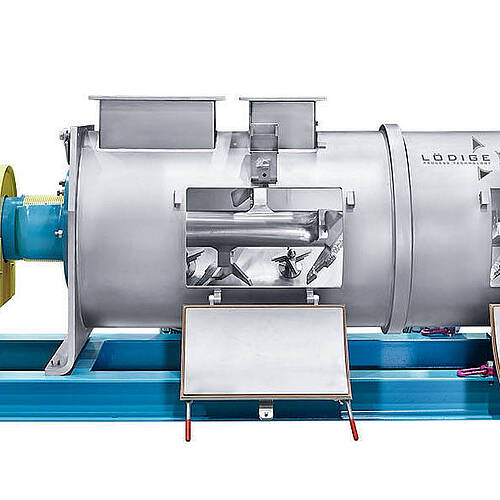

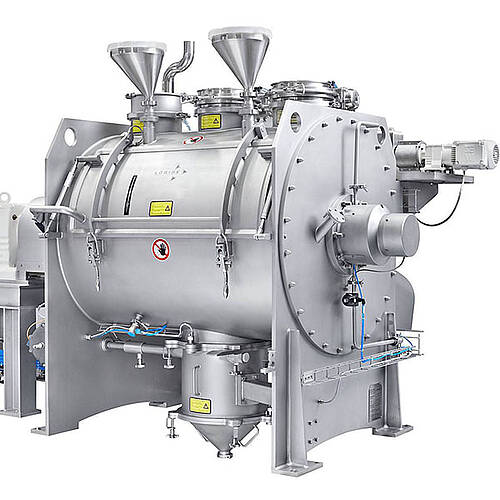

Vacuum shovel dryer DRUVATHERM®

Intense mixing prevents temperature and moisture gradients within the product Maximum heat transfer coefficients ensure excellent dryer performance Gentle thermal product treatment in vacuum mode Multi-phase process (mixing, granulation, drying, cooling) Cost-efficient solvent recovery

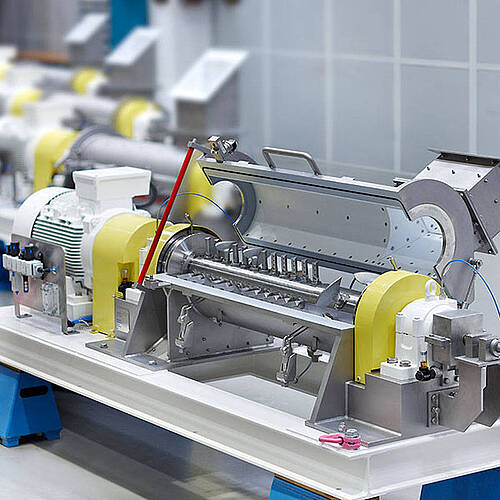

Vacuum shovel dryer DRUVATHERM® (Lab machine)

Reliable scale-up Production development under consideration of industrial factors “All-in-one process” (mixing, granulation, drying, cooling) Intense mixing prevents temperature and moisture gradients within the product Short drying times through intense product movement and effective application of thermal energy Gentle thermal treatment at low temperatures using a strong vacuum Cost-efficient solvent recovery

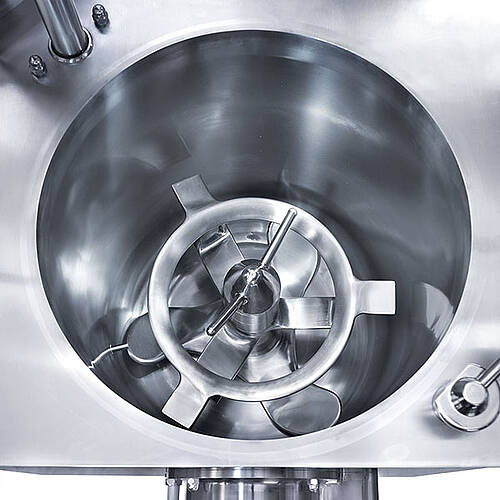

The wet mixer

High mixing quality even for critical products Application of high shearing forces Easy operation and cleaning Reliable and time-tested mixer concept

The mixing granulator

Mixing granulator for pharmaceutical products, cosmetics and food GMP-compliant design Modular WIP system for the machine and all additional components Automatic liquid addition in different versions New pharmaceutical controls Temperature control jacket for heating/cooling Integrated sieve on machine outlet Vacuum feeder Customised ATEX concepts

Mixing granulator (Laboratory machine)

Laboratory mixing granulator with exchangeable vessel Mixing, granulation and temperature control in one machine Exchangeable vessels with a volume of 1, 5, 10 or 15 l GMP-compliant design User-friendly, integrated control system Operation-ready system

Ploughshare® Mixer (Laboratory machine)

Guaranteed Lödige quality Attractive value for money Functional design Ideal for your product and process development Extensive range of accessories

The Lödige high-speed granulator

Versatile application options for the pharmaceutical and food industry GMP-compliant design Usable as a single unit or combined with a cooling mixer User-friendly control system with pre-defined process steps Many additional options available (CIP system, qualification, etc.)

Ringlayer mixer CoriMix® for continuous operation

Compact machine unit with high throughput Extremely high mixing homogeneity Versatile application options Easy operation and cleaning High operating reliability and service life

Coater System

Filling level variability without drum replacement The extremely low height of the mixing elements permits a high degree of filling level variability. Even application and short process times The high number of mixing elements and nozzles ensures ideal distribution and leads to low variance in the evenness of application. High-speed = Time is money The even air distribution throughout the entire drum length ensures that the drying effectiveness is high and permits high spray rates. Optimised air routing: A quality improvement This air routing prevents spray drying, increases service life for campaign production and reduces the cleaning workload. Simple cleaning A sophisticated cleaning system and its great mechanical effect make cleaning quick and efficient. This saves time, cleaning agents and energy.

Coater-System (Laboratory machine)

Innovative design, great functionality Variable filling level between 0.6 and 6.0 l High process speed due to high spray rates and high drying capacity Even distribution of the suspension Process conditions comparable to Lödige production coaters User-friendly: Easy handling, intuitive operation

Reactor DRUVATHERM®

Rapid uniting of reacting agents Prevention of local overconcentrations No temperature gradients within the reaction field Improved conversion of reactin agents, leading to higher yield with greater purity of the final product Multi-phase process (reaction, heating, drying, granulation, cooling)

Reactor DRUVATHERM® (Laboratory machine)

DRUVATHERM® reactor at laboratory scale Rapid uniting of reacting agents Prevention of local overconcentrations No temperature gradients within the reaction field Improved conversion of reacting agents, leading to higher yield with greater purity of the final product Multi-phase proceess (reaction, heating, drying, granulation, cooling)

Fluid bed dryer LCF for continuous operation

Lödige has years of expertise in continuous granulation. Nowadays, continuous ringlayer mixers are established systems for continuous granulation in many industries. However, until now the Lödige product range was missing a suitable dryer. The continuous fluid bed dryer closes this gap. Together with the ringlayer mixer CoriMix® and the customer-specific dosing system, this dryer provides a complete continuous granulation line: GRANUCON®. Dryer operation is based on the fluid bed process. A general disadvantage of continuous fluid beds is the wide retention time distribution within the machine. Lödige’s developers have looked into this problem and have found a solution: integrating a screw in the fluid bed dryer. This has a limiting effect on the retention time distribution.

Ploughshare® mixers for continuous operation "Universal Design"

We develop customised solutions, adapted perfectly to your application and product, for any of your tasks. Excellent homogeneity of the final product Retention/mixing times and granulation processes can be adapted to the specific product Gentle product treatment Consistent reproducibility High availability Easy accessibility of all internal mixer components Low-maintenance mixer concept

Ploughshare® Mixers for batch operation "Hygienic Design"

We develop customised solutions, adapted perfectly to your application and product, for any of your tasks. Extremely high mixing quality Short mixing times Reproducibility of batches Gentle product treatment High availability Low-maintenance mixer concept Easy accessibility of all internal mixer components Multi-stage processes in one machine

Ploughshare® Mixers for batch operation "Universal Design"

We develop customised solutions, adapted perfectly to your application and product, for any of your tasks. Extremely high mixing quality Short mixing times Reproducibility of batches Gentle product treatment High availability Low-maintenance mixer concept Easy accessibility of all internal mixer components Multi-stage processes in one machine